4 Years to Kill a Spreadsheet: Automating Manufacturing at Fictiv

Lead designer 2020 to present

Background

Manufacturing is a complex and mostly manual industry. Its notoriously slow and if you have been there you know that finding the right manufacturer that has the right capabilities, machines, and quality is a huge task. This process can take months but with on demand manufacturing companies it has openedthe doors for fast high quality parts. Every on demand manufacturing company has a different model most of them rely sole with on line job boards but fivtic was different fictiv built a model around direct job matching which is hard to orchestrate. It requires so many factors to achieve the fasted highest quality which is why it took 5 years to accomplish. When I joined Fictiv in 2020, scheduling was a multi-system nightmare:

3rd party ERP system (accessed via slow VPN)

"scheduling spreadsheet" - a legendary Google Sheet with complex formulas

human knowledge around capabilities and manufacturing processes.

It wasn’t as simple as to say let’s automate this we needed to create the blocks. over a period of 4 years I built these systems from dashboards , to order milestones, to capabilities, and autobundling. These were the foundation.

What was the Fictiv Process?

1. Customer orders parts → Sales order broken into individual parts

2. Schedulers manually bundle parts into manufacturing jobs (one big job vs. multiple for speed)

3. Use spreadsheet to find right MP based on capabilities, region, quality

4. Manually sync to ERP system

5. Wait for manufacturer to accept

The Strategy

The operations workbench is an internal web-based application that is an integral part of the entire customer experience. It is the waiter in a restaurant that is the liaison between the customer and the manufacturing partners. Without this suite of products, orders could not be sent to manufacturers, tracked by customers, or inspected for quality by quality control. When I started in 2020 the operations workbench consisted only of a quality control dashboard all operations were conducted either on Google spreadsheets or various 3rd party software like Sigma, Airtable, Odoo, etc. This created a ton of workflows and inconsistent data metrics that could never be tracked by Fictiv. As Fictiv grew it needed a mature suite of software that it could build upon where data could be tracked and single workflows could be used across regions.

Who are the users:

This application has multiple users across 4 regions USA, Mexico, India, and China.

TPM (Technical program managers)

SQE (Supply quality Engineers)

QA (Quality Assurance)

Operations Leaders

Executive level teams

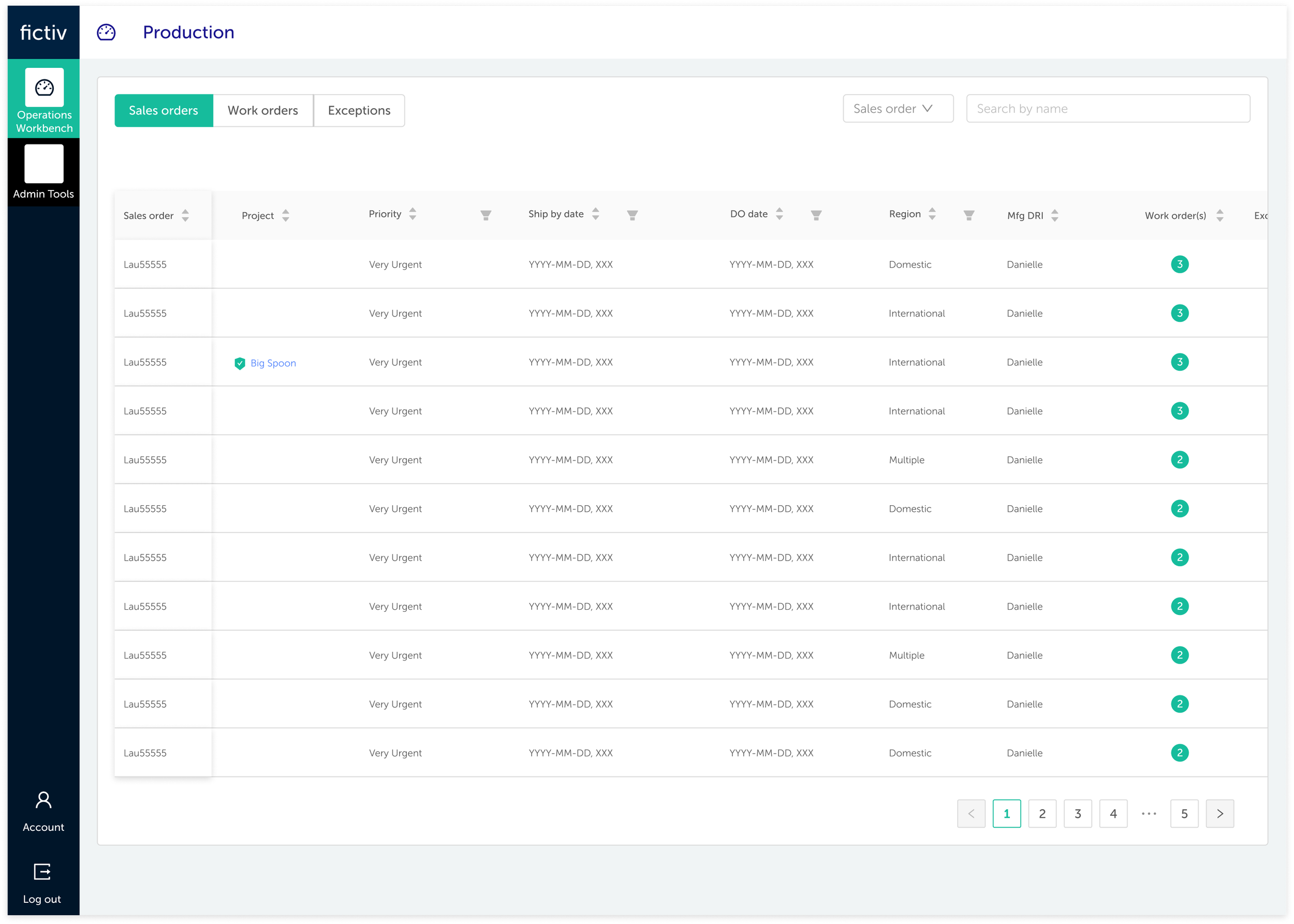

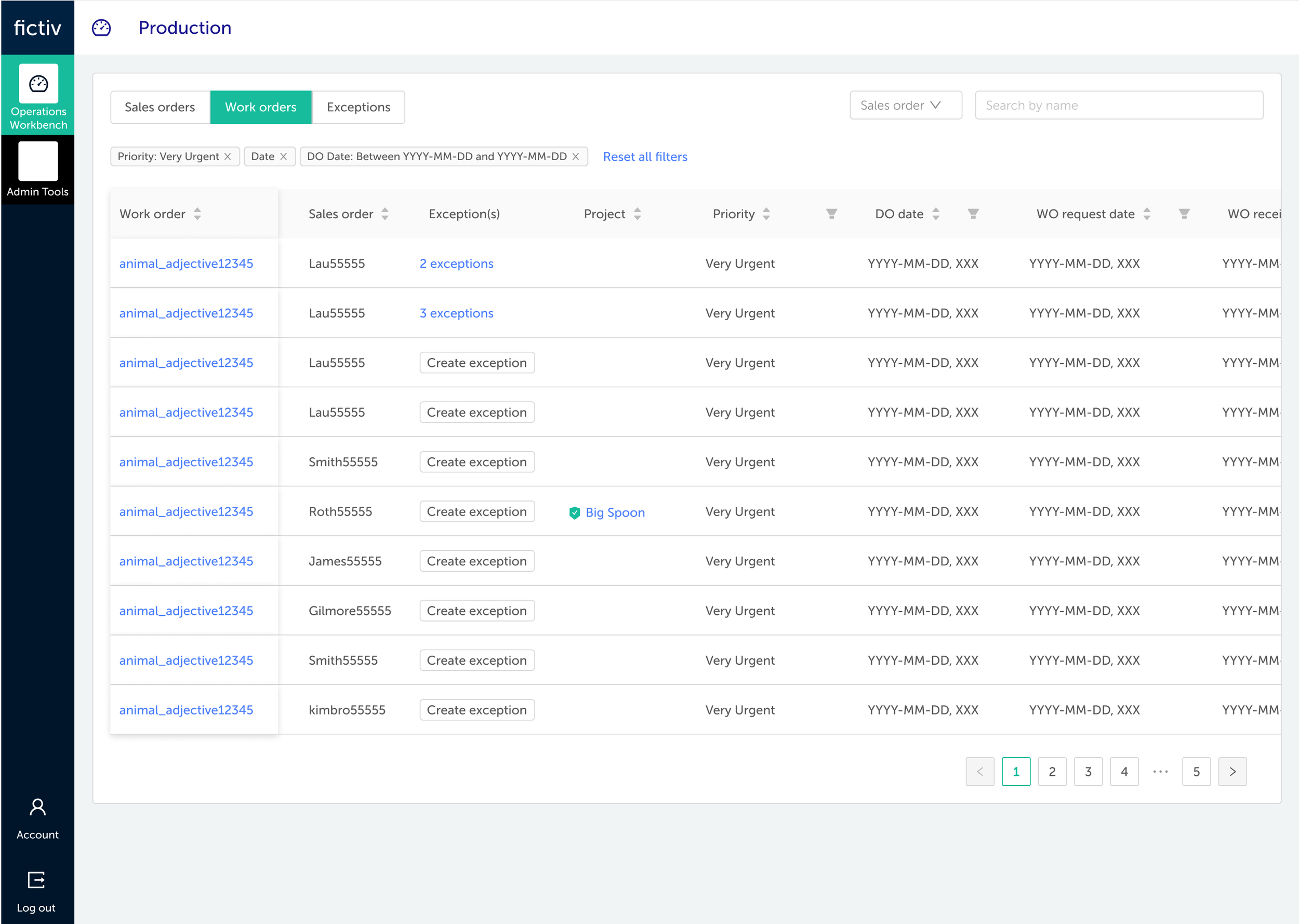

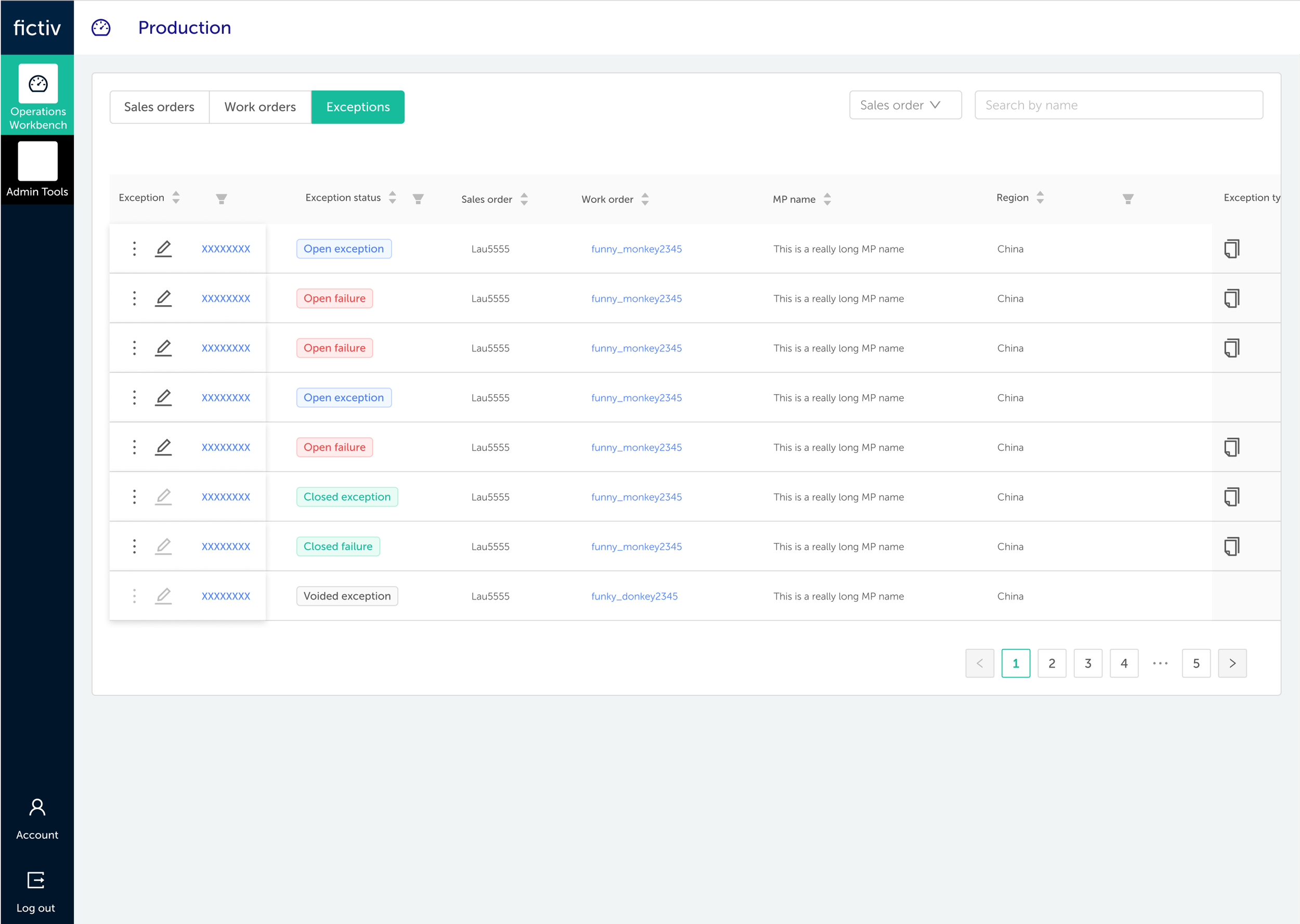

Product 1: Dashboards

Our initial focus was on developing a comprehensive dashboard for orders, jobs, and exceptions. Upon delving into the issue, we discovered that users were spending valuable time manually transferring order and job details to external tools such as Airtable and Google Sheets. In response, we leveraged our ERP software to automatically gather and present order information across three dedicated tabs. This innovative approach eliminated the need for manual data entry, significantly enhancing efficiency. Since their inception in 2020, these dashboards have undergone iterative improvements, but their original design marked a pivotal advancement in streamlining processes.

Product 2: Job Creation

After establishing our foundational dashboards, our attention shifted to the next phase of the product, which involved the creation of jobs. This step enabled manufacturing partners to produce parts within a given order. Fictiv employees take unbundled parts, generated by the ERP system, and undertake a series of actions to create multiple jobs or a single job for a specific order. The jobs can be created in multiple ways such as by process, quantity, secondary process, and even production country.

Product 3: Job Scheduling

Following the creation of jobs, the subsequent phase involves selecting a manufacturer from the Fictiv network to undertake the job. This particular screen holds paramount importance, being the most frequently used within our software suite. Timely scheduling is crucial, as a missed schedule can trigger a cascading effect throughout the process, potentially leading to delays in part deliveries. The scheduling interface is dynamic, offering users the ability to route jobs to different regions, modify scheduling types, add notes to manufacturers, adjust payouts, and set due dates. Additionally, users can communicate directly with manufacturing partners (MPs). I introduced a unique "playlist" UX, allowing users to queue multiple MPs and initiate an autorun of the queue. This streamlined approach not only saves our internal users considerable time but also enables them to efficiently manage multiple job requests, waiting for responses in a more organized manner.

Product 4: Order Tracking

Once an order is created and scheduled by a manufacturing partner (MP), it gains the capability to be tracked to ensure timely delivery to the customer. The tracking process involves six distinct milestones for each part, serving as a communication tool with customers to inform them of their parts' location. This tracking system is instrumental for operations users, providing a visual representation of the order's progress. An interactive progress component has been implemented, employing color-coded indicators for on-track (green), at-risk (yellow), and off-track (red) statuses. Users can hover over each progress area to view relevant dates in a popover, facilitating quick assessment for recording exceptions or flags on the order. Notably, the progress tracker is not confined to a single table; it is prominently displayed on all crucial dashboards and pages, ensuring internal operations have seamless access to monitor job progress across the board.

Product 5: Proactive Management Tools

Recognizing that not all orders proceed as initially planned, we've implemented a crucial feature to proactively address potential delays in delivering orders to customers on time. Users now have the capability to flag a job for monitoring, ensuring a proactive and transparent approach. This feature facilitates full transparency by allowing users to write internal notes, assign an action plan, and notify team members to take specific actions through various communication methods. It serves as a powerful tool to mitigate challenges and maintain control over the order fulfillment process, enhancing overall operational efficiency.

Product 6: Quality control

Our quality control dashboard empowers users with the ability to conduct virtual quality control seamlessly. This innovative feature enables manufacturing partners (MPs) to upload inspection documents and photos directly into the system. This streamlined process not only enhances the efficiency of quality control but also ensures a thorough and visual examination of the manufactured parts. Users can access a centralized platform to review inspection details, analyze images, and make informed decisions about the quality of each component. This integration of virtual quality control not only accelerates the QC process but also contributes to maintaining the highest standards in product quality and customer satisfaction.

Product 7: Change Management

In the course of the manufacturing process, challenges can arise leading to job or part failures. To address such instances, we initiate a corrective action plan, a pivotal step for not only identifying the root cause of the issue but also implementing measures to prevent its recurrence. Traditionally, this process is documented on physical paper or spreadsheets, and initially at Fictiv, it was managed through a Google Form. However, the completion rate among manufacturing partners (MPs) was only around 10%, as the freeform questions posed challenges in understanding and responding comprehensively. To enhance the efficacy of this process, I introduced a form-like interface where MPs can select from a dropdown list of possible answers and provide a detailed freeform description. This redesign resulted in a significant improvement, increasing completion rates from 10% to an impressive 90%, facilitating a more streamlined and effective corrective action process.

What is the future?

The future of our product envisions a heightened focus on automation and efficiency, building upon the solid foundations we've established. This strategic direction involves the implementation of automated order creation, automatic scheduling, digitized inspections, and streamlined communications. The goal is to optimize processes, reduce manual intervention, and enhance overall operational efficiency.

What are the challenges of working on this product?

One prominent challenge is dealing with unanticipated edge cases. Given the diverse range of customer products, each with its unique specifications, it's nearly impossible for the design team to anticipate every potential edge case. While this poses a drawback, it has motivated the team to adopt a strategy of releasing products faster, allowing for iterative improvements based on real-world usage rather than attempting to account for every possible scenario.

Another challenge lies in managing time zones, as the product team is distributed across multiple regions. This necessitates a high level of discipline and asynchronous interaction to ensure effective collaboration despite the geographical dispersion. Overcoming these challenges is integral to maintaining agility and responsiveness in the evolving landscape of our product development.

Detailed project process is available on request.