Helping manufacturers keep track of jobs from customers using organizational kanban tools.

MES portal for manufacturing

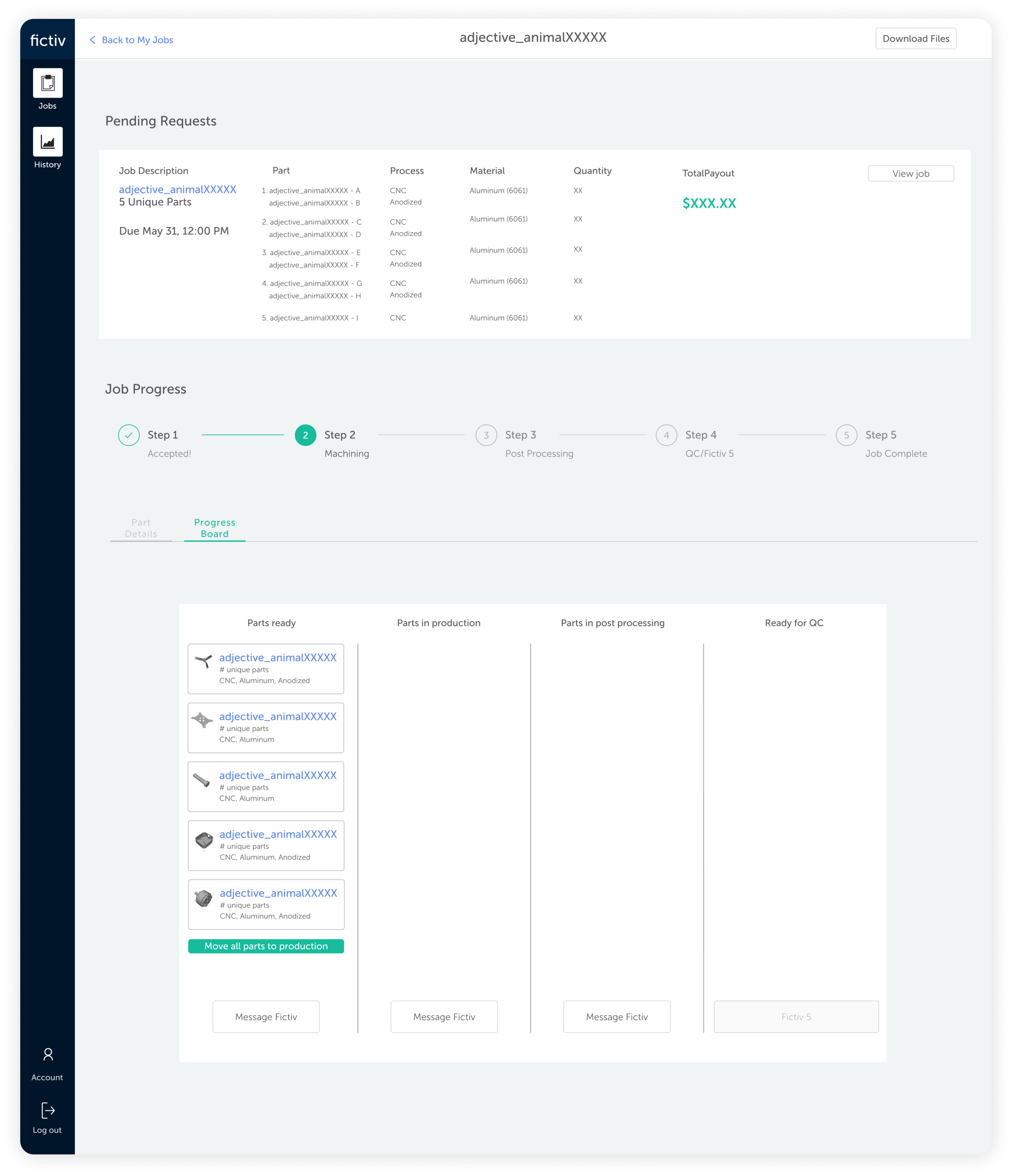

The Outcome

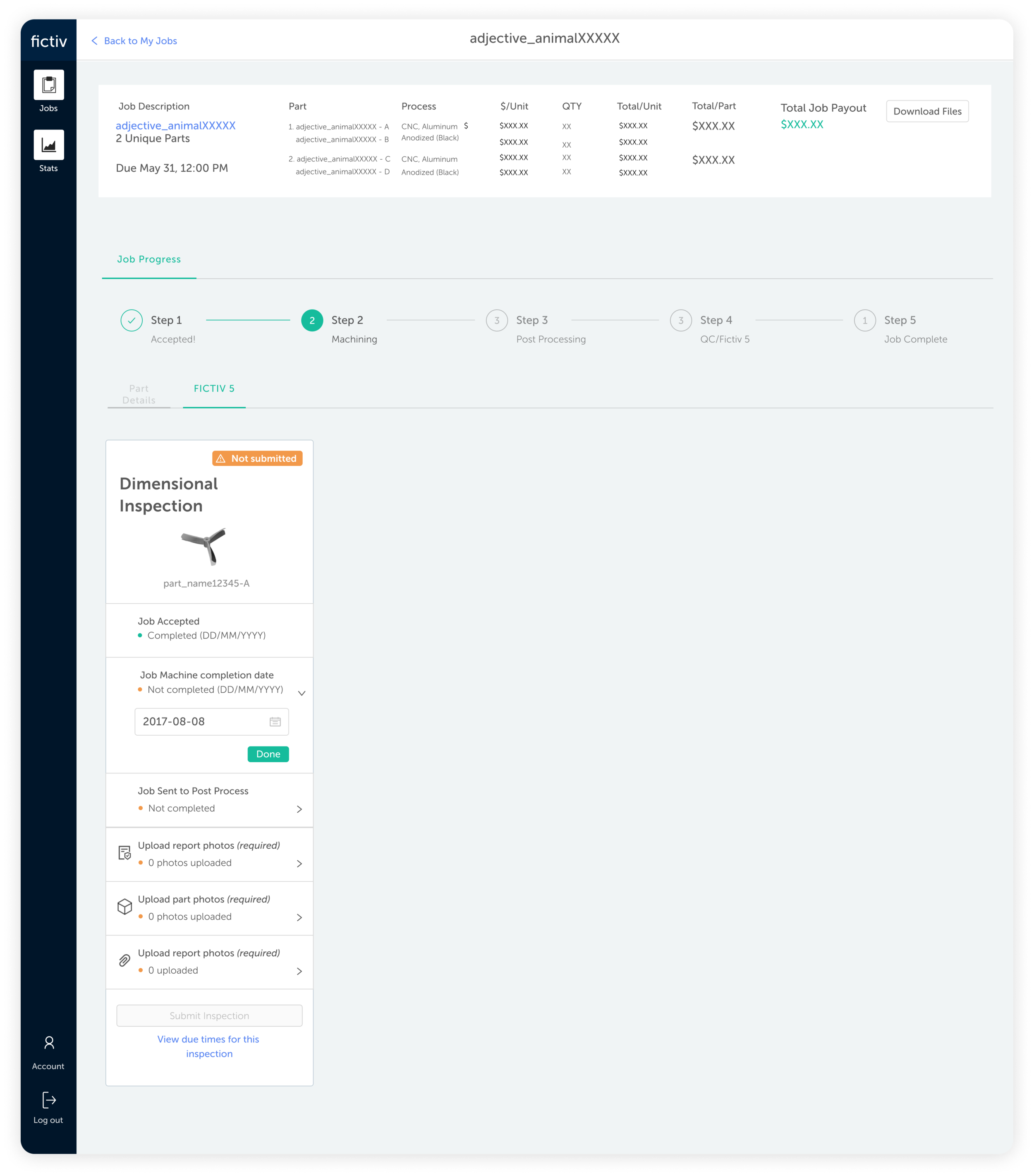

A redesigned interface that enhances job management for MPs by organizing tasks around key milestones, prioritizing essential job details, and optimizing the experience for mobile use.

The Challenge

Workbench is a product on the Fictiv platform in which manufacturing partners can log in to accept, manage, and inspect jobs for Fictiv customers. The original platform had been built in 2018 and it needed an overhaul to scale for larger manufacturers and more complicated manufacturing processes. The team’s goal was to think differently about how the system could not only accommodate Fictiv’s need to grow its core product offering but also to improve the efficiency of the manufacturers so that jobs can be completed on time.

Role: Lead Product Designer

Phase 1: Discovery

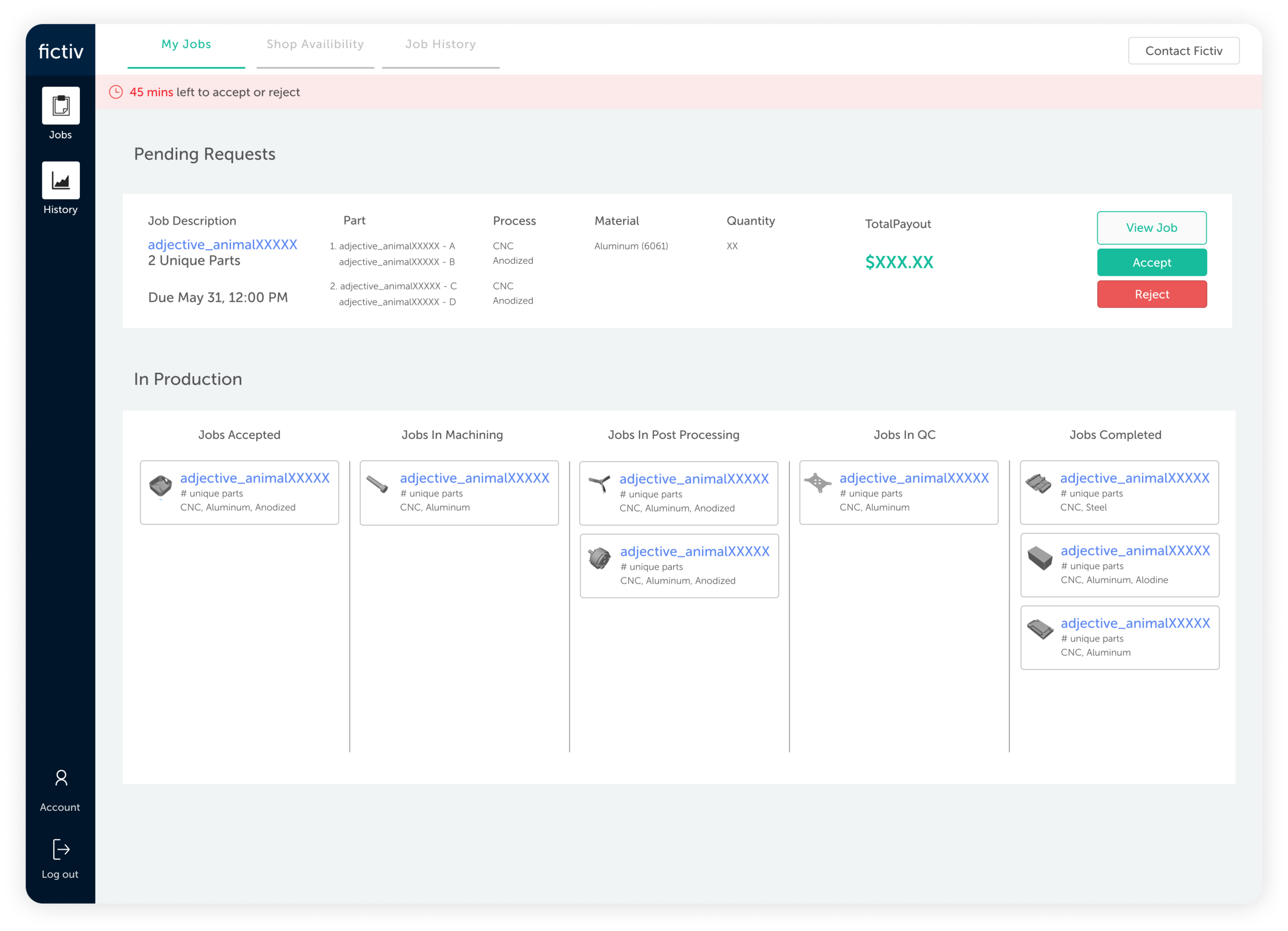

Old UI

Observations/Painpoints:

Lack of initial information when first logging in to view a job request. Manufacturers were spending an average of 45 minutes downloading parts and connecting the details to evaluate and accept a job which took time away from the fabrication process.

Organizing part details by individual process caused manufacturers to overlook the jobs which resulted in high OTIF (On Time In Full) failures. Not only did this affect the manufacturer’s level score it also caused low satisfaction rates with customers.

The customer had no visibility into the status of the order because the manufacturer only logged in to accept and complete the job.

Most Importantly:

The manufacturer had no way of organizing their workflow and managing their jobs.

Actual project management hack a manufacturer was using.

Phase 2: Exploration

How might we design a better way for manufacturers to organize and manage jobs?

I tested out various design concept layouts and workflow prototypes with manufacturers by asking them how we could better help them organize and manage their jobs.

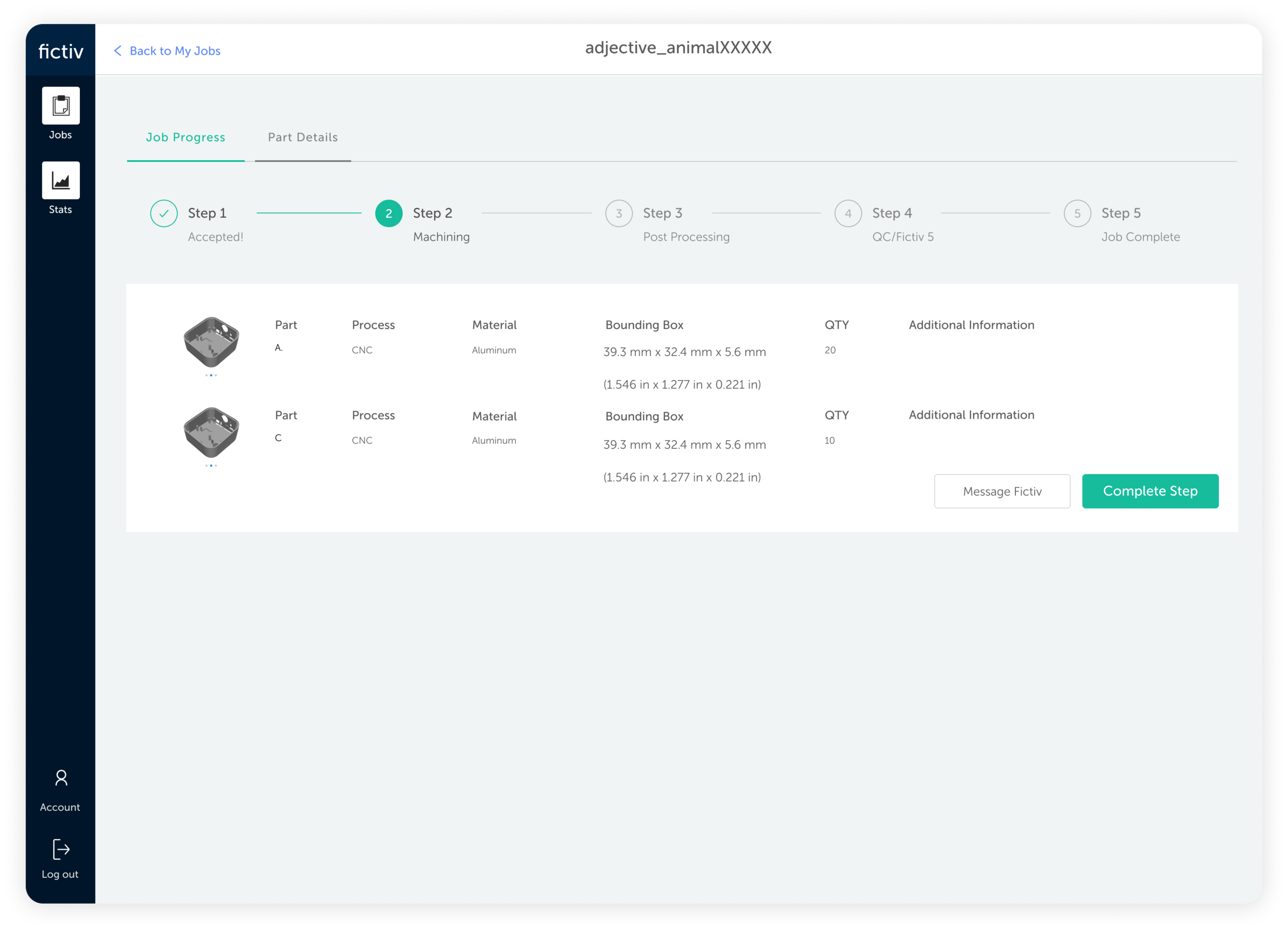

Make it clear which step of the process the user was on.

Differentiate part processes vs products and pending job requests vs accepted job requests.

Make information about a pending job more accessible by giving it a visual hierarchy.

Workflow iterations

Design Direction

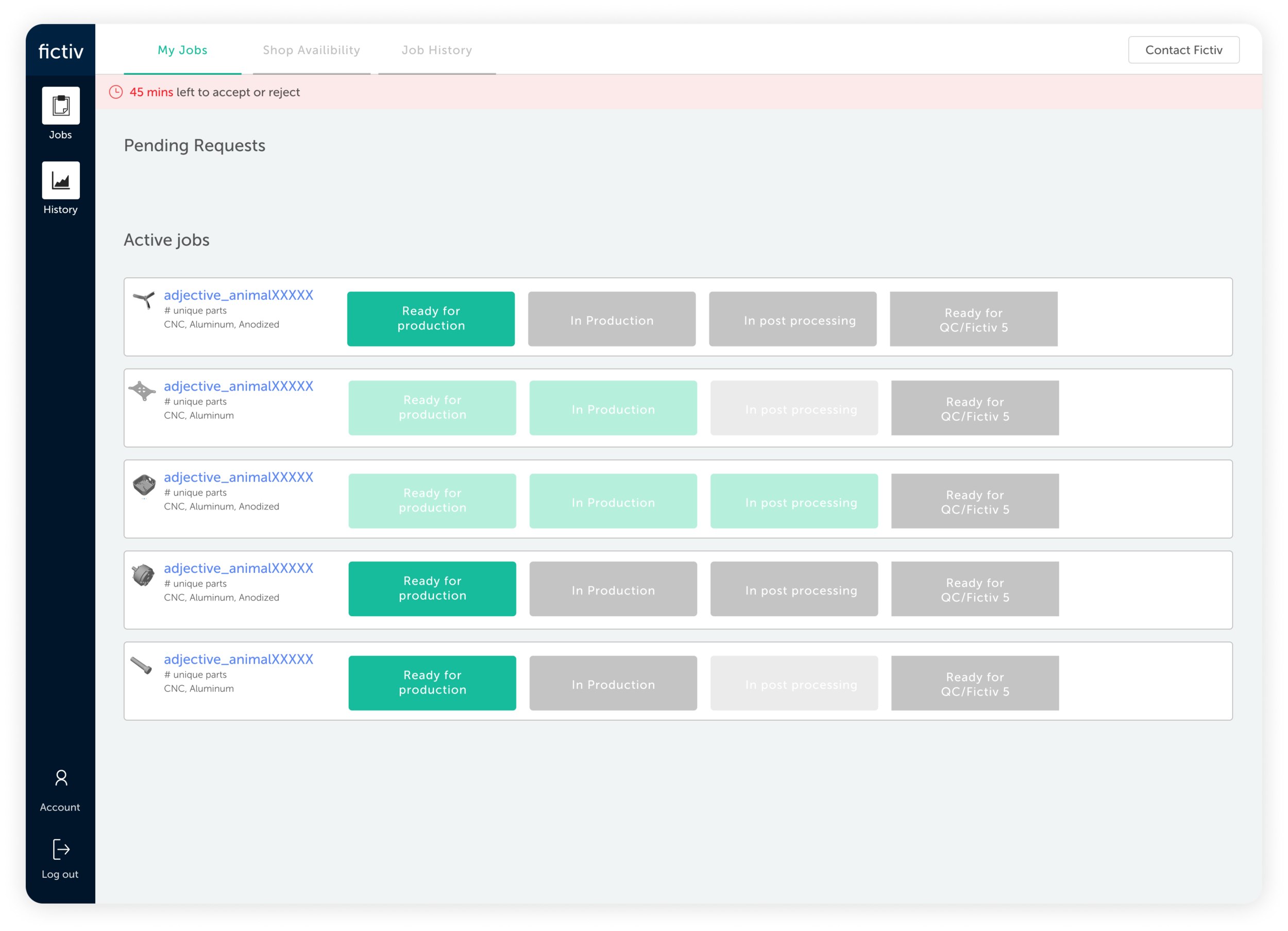

“This concept works the best because it’s a method we already use inhouse on a whiteboard or clipboard”

A kanban style design was chosen because it helped manufacturers stay on track and organize their jobs better.

When the MP moves a job across the categories it triggers the progress of a job while the MP is working on it, an area that had no visibility before. The benefit of this is that Fictiv can now create progress trackers that can help stakeholders manage jobs and ultimately communicate better with customers.

Helped the MP differentiate pending jobs vs jobs in progress better than the other concepts.

UI Refinement

Full UX flow

Summary and next steps

Designing for hundreds of jobs: something that was not anticipated at the time of the first iteration of this was an MP that has hundreds of jobs with Fictiv.

Adding more categories: a post-release feature that is in the roadmap is to add programming and tooling categories so that the Kanban board has more granularity.

In-app notifications: email notifications are incredibly inefficient and MPs don’t check them as often and sometimes miss them. This is challenging and sometimes results in inaccurate movement of jobs across the kanban board.